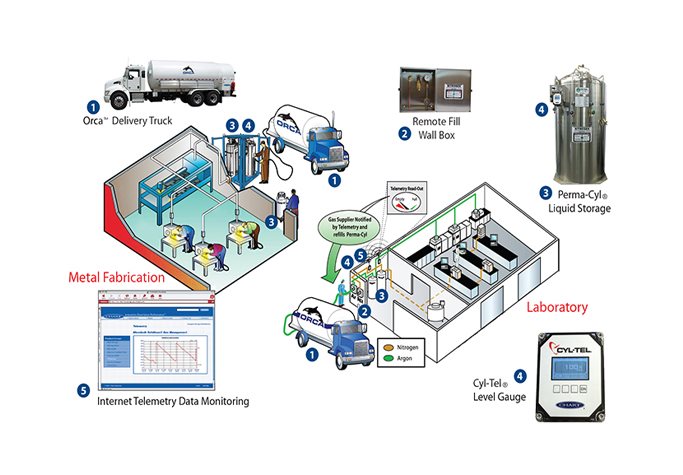

Distribution & Storage

Engineering and manufacturing in Italy and India for the complete range of products for the storage, distribution and vaporization of liquid gases including nitrogen (LIN), oxygen (LOX), argon (LAR), carbon dioxide (LCO2), nitrous oxide (LN2O), hydrogen (LH2) and natural gas (LNG) complements Chart's facilities in the US, Europe and China. Fully integrated with products supplied according to Chart standards, specifications and approvals.

Energy & Petrochemicals

Custom engineered specialty heat transfer and pressure containing products including reactors, drums, separators and shell and tube heat exchangers serving the refining, petrochemical and fertilizer industries. High pressures, temperatures and exotic metallurgy are specialisms. Support through the complete product lifecycle from feasibility studies to comprehensive aftermarket services. Engineering and manufacturing center of excellence is in Italy.

.jpg?ext=.jpg)

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team