Howden Uptime

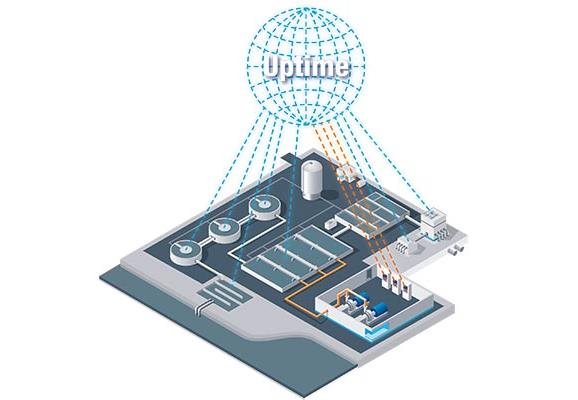

A unique digital solution for equipment performance optimization that seamlessly gathers and integrates the physical sensor data from any type of rotating equipment, and analyses how it operates and responds to the environment.

Howden combines over 160 years of OEM expertise with the most advanced industrial IoT architectures in the world, to provide a purpose built, innovative platform to deliver value to our customers. Our unique digital solution has been installed on equipment in a wide range of industries; from oil & gas, to power, to wastewater and general industries, and is compatible with non-Howden equipment.

Howden Uptime is a digital platform that seamlessly integrates data related to your rotating equipment's performance. The system combines active inputs, such as temperature, pressure and vibration, with reference parameters from manuals, specifications and maintenance reports. When the data is analysed, it provides a unique foundation for maintaining and enhancing operational excellence.

Through Howden Uptime we're no longer just the manufacturer but a trusted advisor helping to keep equipment running smoothly and improving the customer's operational success.

The unique Howden digital twin is at the heart of the Howden Uptime solution. It creates a digital profile of the Howden product and is purpose built for individual products and applications. It compares the original design data, the set of parameters within which we know the equipment should be operating, with the operational data.

The system combines active inputs, such as temperature, pressure and vibration, with reference parameters from manuals, specifications and maintenance reports. When the data is analysed, it provides a unique foundation for maintaining and enhancing operational excellence.

Identifying these differences in operation early allows for corrective actions to be put in place, mitigating risk that would have otherwise gone unnoticed and could result in unplanned downtime.

Howden Uptime provides a 24/7 real-time view of your equipment's operational performance, if any of the parameters fall outside the recommended limits then there will be an alert sent with corrective action.

The data is shown live on the Howden Uptime platform, which can be accessed anywhere with an internet connection. The dashboards on the platform show the master view of all assets, with an overview of the performance status, you are then able to drill down into each individual asset and component to show specific sensor data and trends.

Understanding how your equipment is operating and being able to identify potential breakdowns before they happen, reduces the risk of equipment failure and ultimately reduces unplanned and costly downtime.

Howden Uptime provides an extremely cost-effective way of raising performance and production time to the highest levels, while reducing total cost of ownership. Learn more from real world examples below.

We integrate our solution with existing systems in your plant to ensure you are not just getting more data, but the most valuable data that is easy to interpret and provides actionable insights.

Howden Uptime provides a direct link to Howden experts, with engineers close at hand at all times to provide expert guidance and support.

Through the secure platform, you get access to the most up to date manuals and drawings, generated health reports and a view of your operating trends over time.

Access and download literature, specifications, case studies and more.

Head Office +44 141 885 7500