LNG Liquefaction Plants

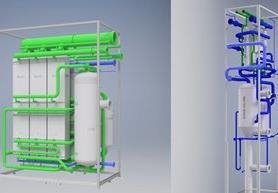

Chart's modular liquefaction plants and associated process technology enable displacement of liquid fuels through small- and mid-scale LNG.

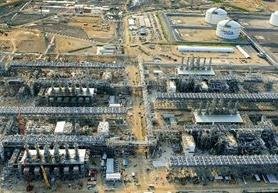

Chart defined small-scale LNG through a range of standard plants with capacities ranging from 3,000 gallons per day (10 tons per day) to 450,000 gallons per day (725 tons per day). Chart’s mid-scale modular model challenges the traditional paradigm that a large baseload LNG facility provides the best economy of scale.

In contrast to the risk profile and upward CAPEX of a traditional baseload liquefaction plant, Chart's mid-scale solutions use multiple, smaller modular LNG trains that allow clients to scale projects according to market conditions and expand capacity as demand grows. Modular solutions are quicker to market and thereby generate faster revenues for stakeholders.

Chart’s IPSMR® process technology provides significantly better efficiency and superior performance over other comparable technologies and makes it possible to optimize liquefaction systems over a wide range of site conditions. IPSMR® process technology can be configured to match available gas turbine power with single cold box capacity to >4 MMTPA.

Brazed aluminum heat exchangers provide optimal thermal performance and operating efficiency versus other heat exchanger types and are at the heart of our standard and modular plant solutions and process technologies.

Hudson air cooled heat exchangers reduce plot space and deliver significant cost savings in LNG liquefaction plants.

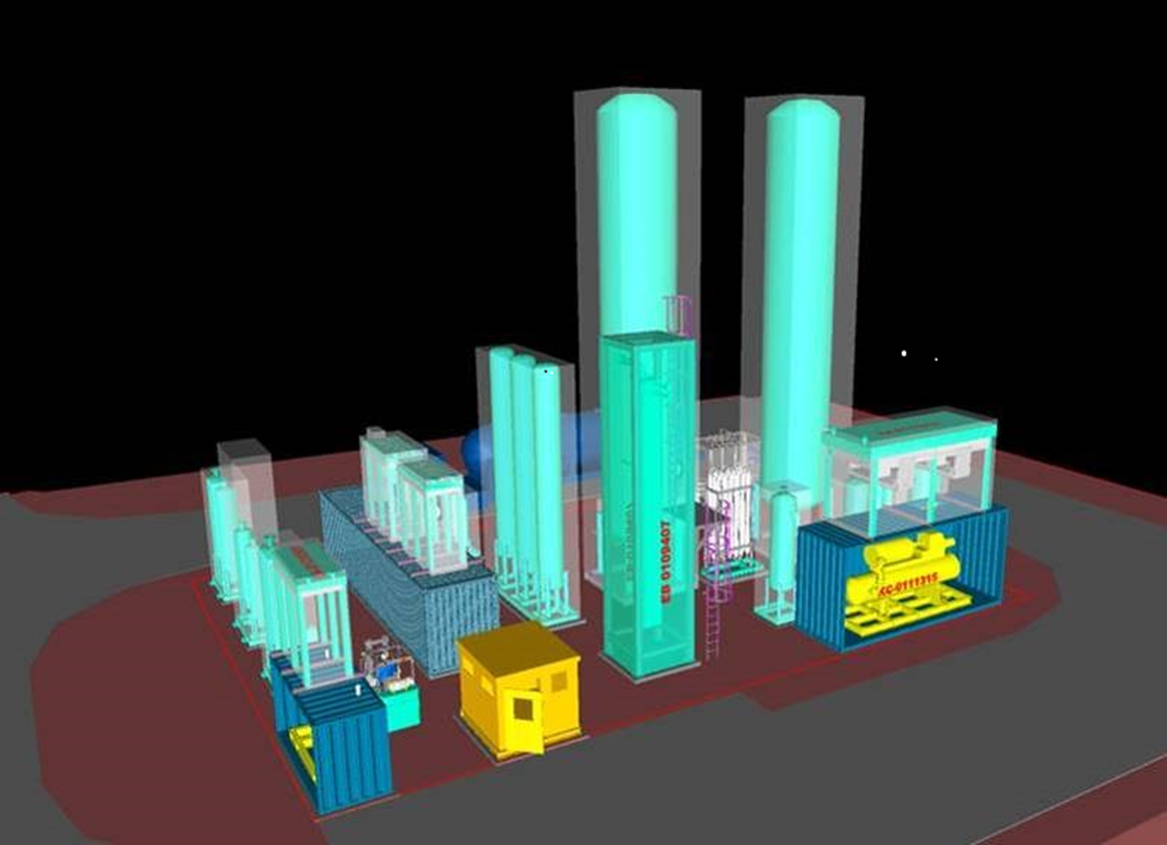

Commercially viable solution for the liquefaction of smaller gas volumes typically associated with biogas. Chart's C15MR Micro LNG liquefaction plant enables customers to recover and monetize methane produced during anaerobic digestion processes.

BioLNG is defined as the highly sustainable version of LNG, has virtually identical chemical properties and can be used at source for power generation, natural gas vehicle fueling, bunkering, loaded into cryogenic containers and transported for regional use or vaporized and injected into the pipeline.

Plant features include:

FLNG refers to the process of developing offshore, or near shore, natural gas reserves using a floating facility that incorporates raw gas processing, liquefaction and storage. The floating units can be platforms or converted ships/barges, the latter typically slated for small- and mid-scale FLNG projects.

As with all offshore projects, minimized footprint, modularization and reliable equipment performance in a harsh environment are all pre-requisites, hence why Chart critical cryogenic and rotating equipment has a proven pedigree in many FLNG projects, including, reportedly, the first floating vessel to produce LNG in 2016.

Chart FLNG equipment scope includes:

View and download sales literature, technical manuals, case studies and more

Telephone +1 281 364 8700

270000

of carbon dioxide emissions saved

More than 10,000 deliveries of clean burning natural gas have prevented 270,000 tons of CO2 being emitted into the atmosphere as well as > 3,000 tons of SOx, > 12,000 tons of NOx and > 150 tons of particulates.