.jpg?ext=.jpg)

Brazed Aluminum Heat Exchangers

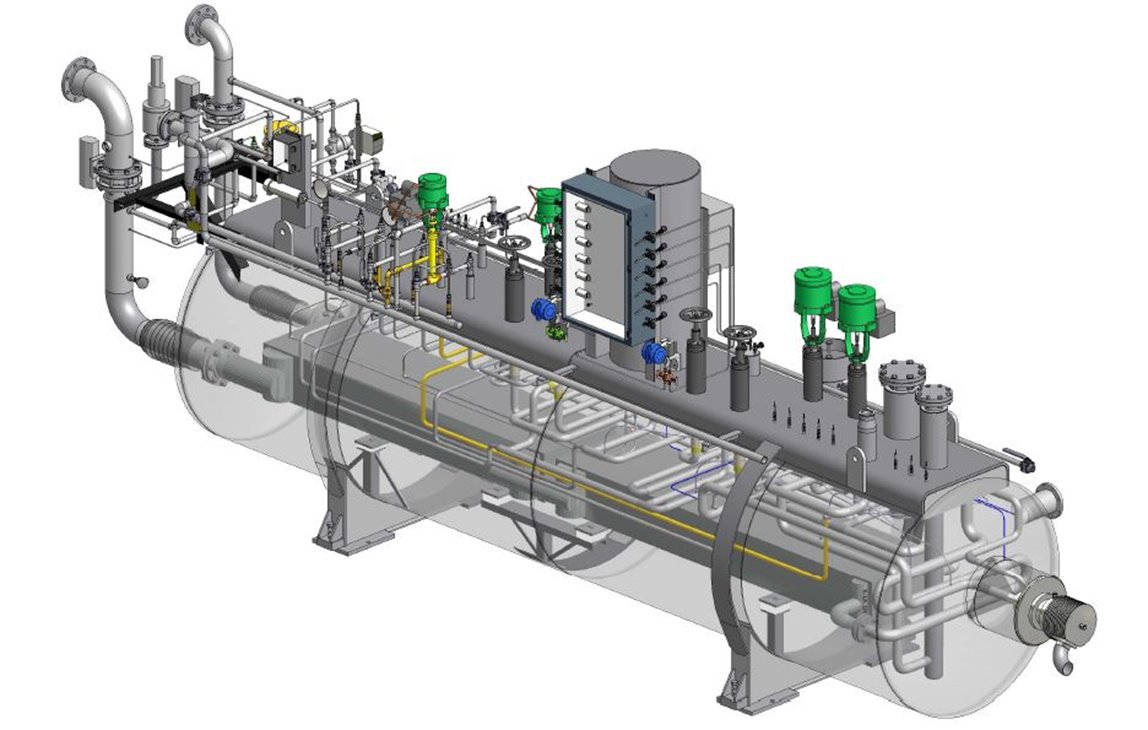

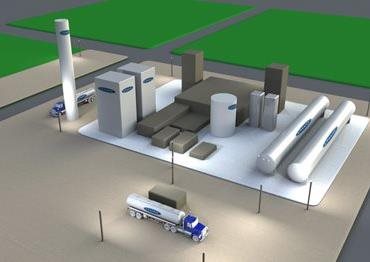

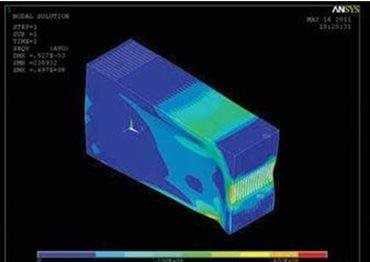

Chart’s Brazed Aluminum Heat Exchangers (also known as Plate Fin Heat Exchangers) and Cold Boxes are at the heart of cryogenic separation, liquefaction and purification processes for air gases, natural gas, hydrogen, helium and petrochemicals.

-683x475.jpg?ext=.jpg)

.jpg?ext=.jpg)

.jpg?ext=.jpg)

.jpg?ext=.jpg)

-1-png.jpg?ext=.jpg)

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team