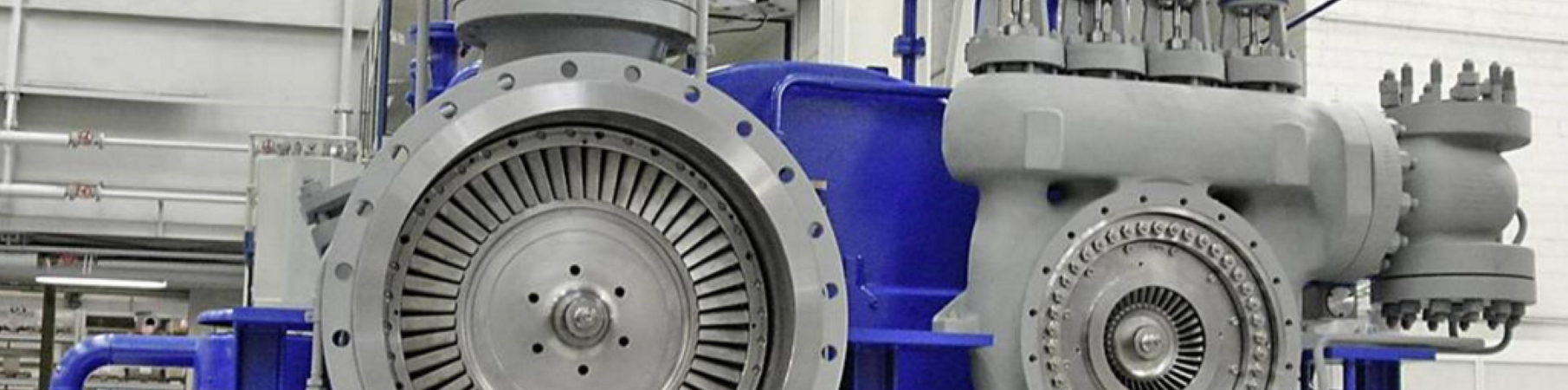

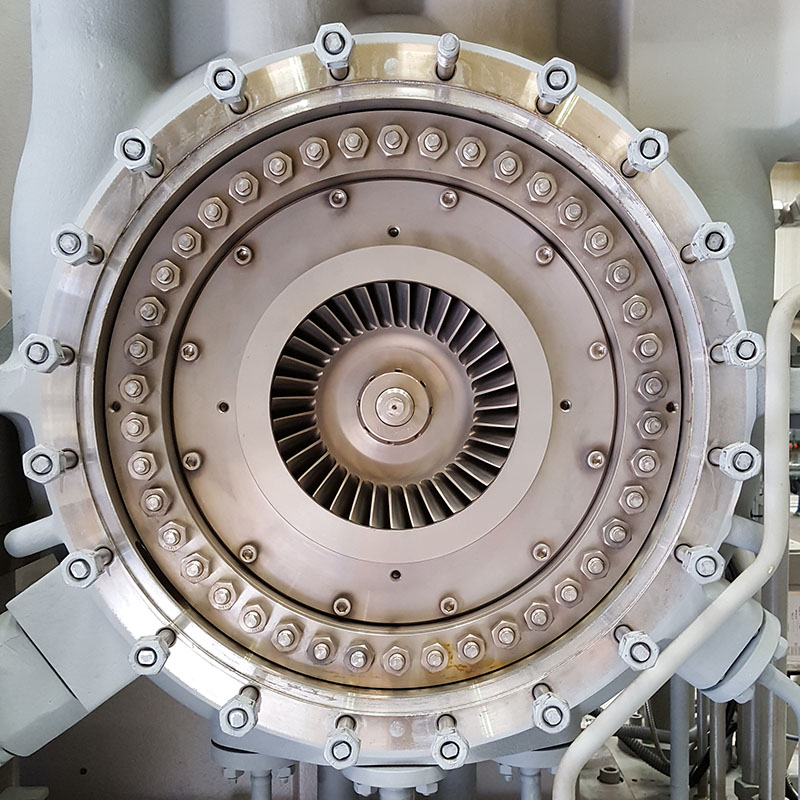

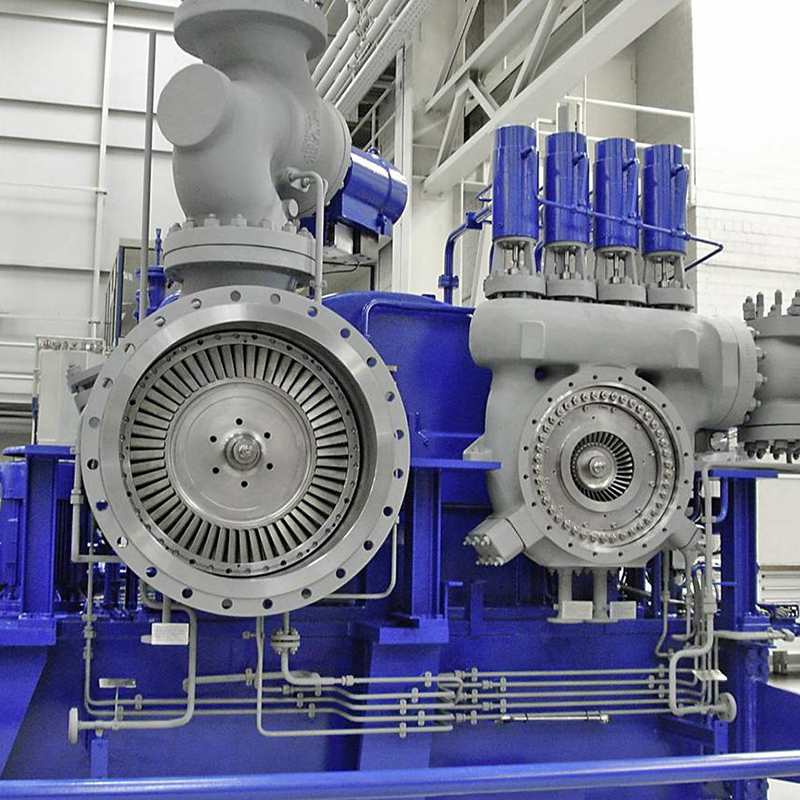

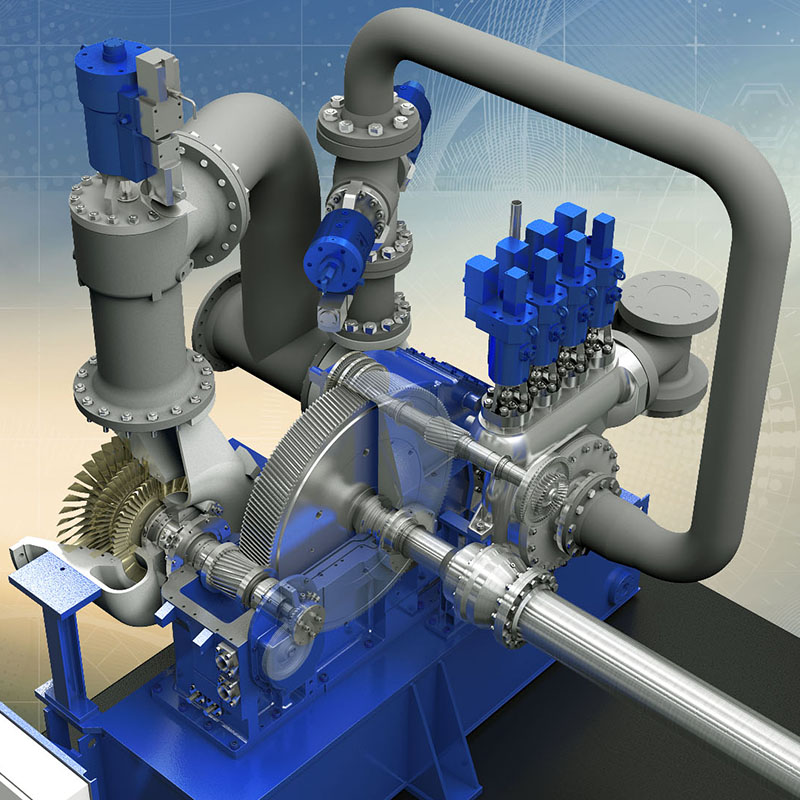

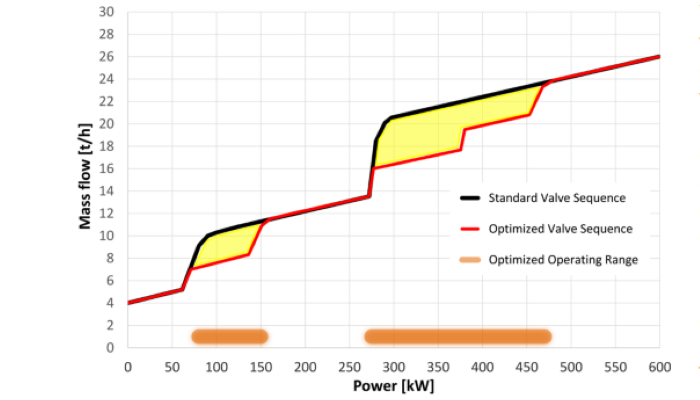

Increasing Performance

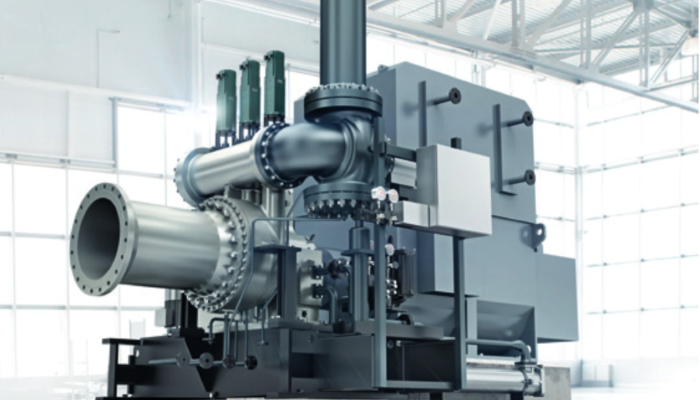

Industrial processes are subject to operational fluctuations where steam turbines need to react flexibly to process changes and to operate efficiently in part load or with fluctuating steam parameters. To optimize part load performance a method is developed to optimize the turbine and the control logic to the actual part load operating condition.

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team