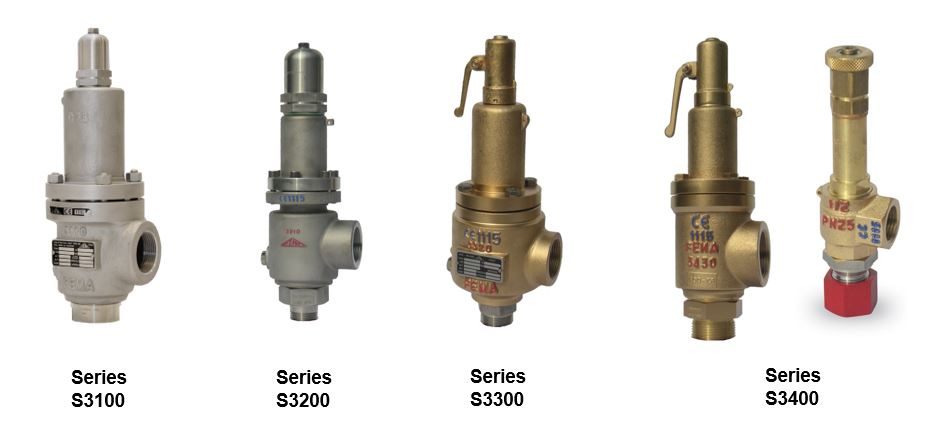

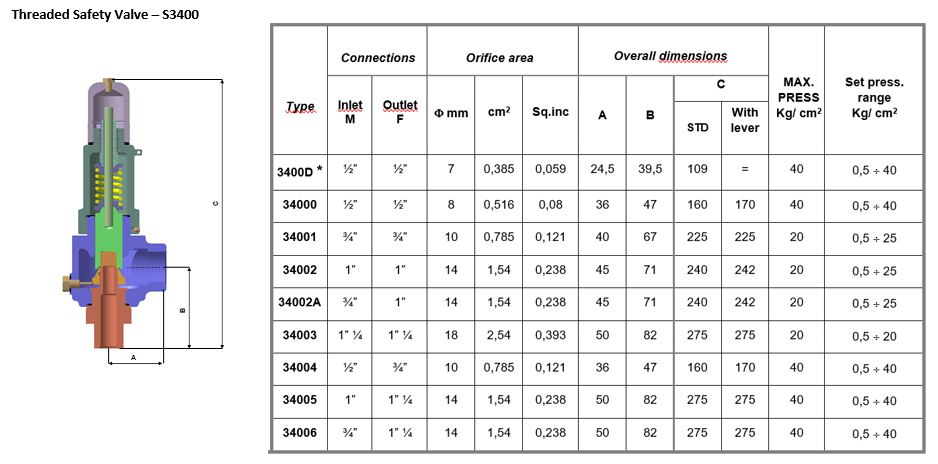

Safety Valves

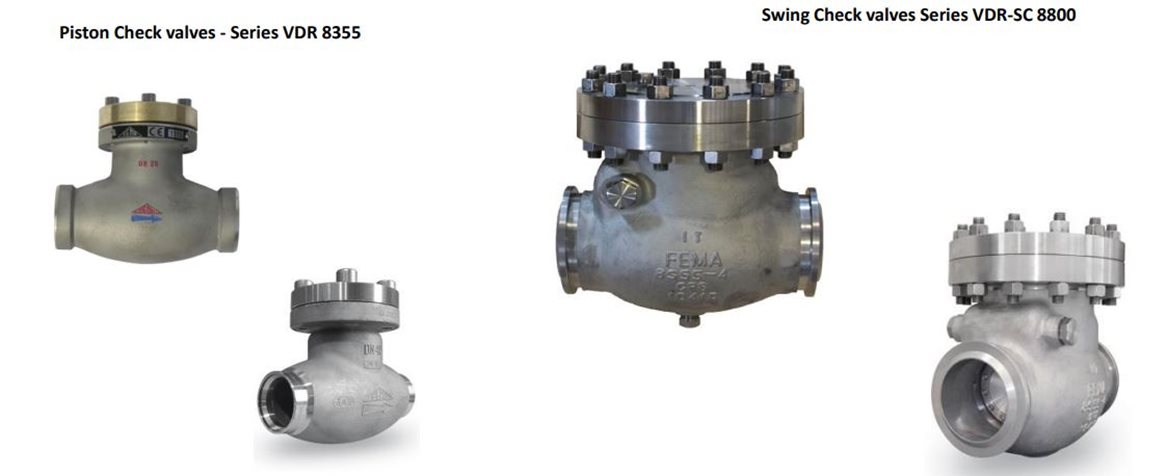

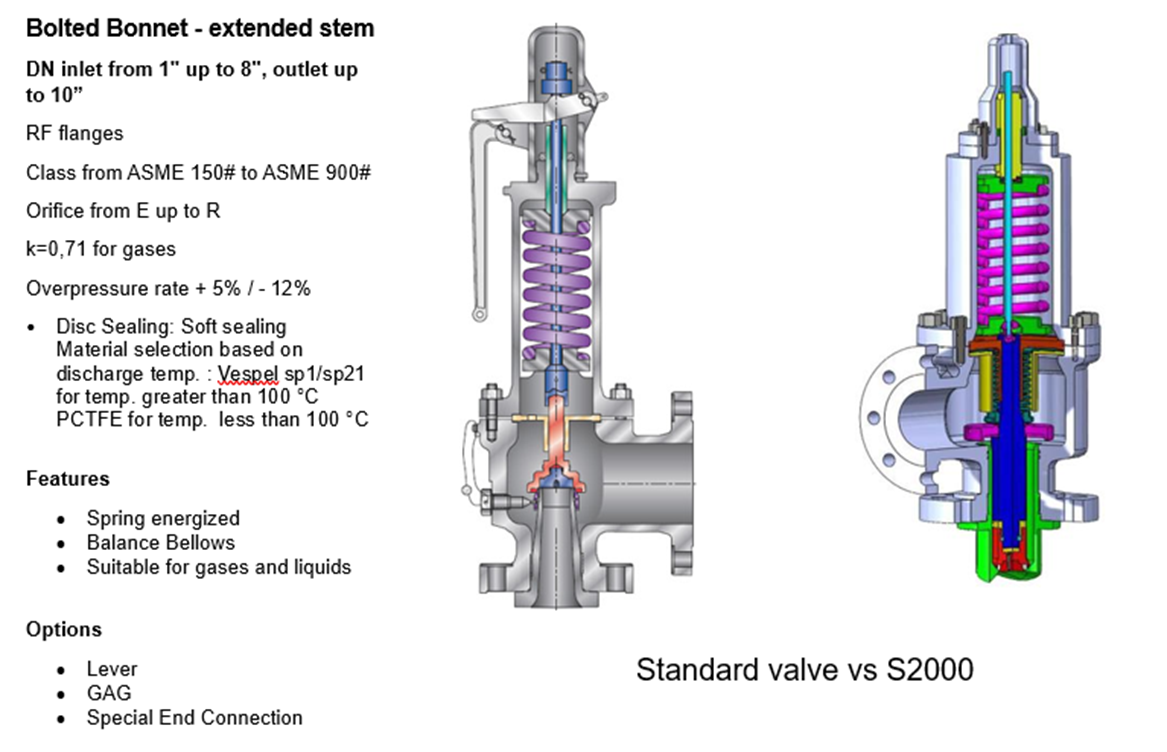

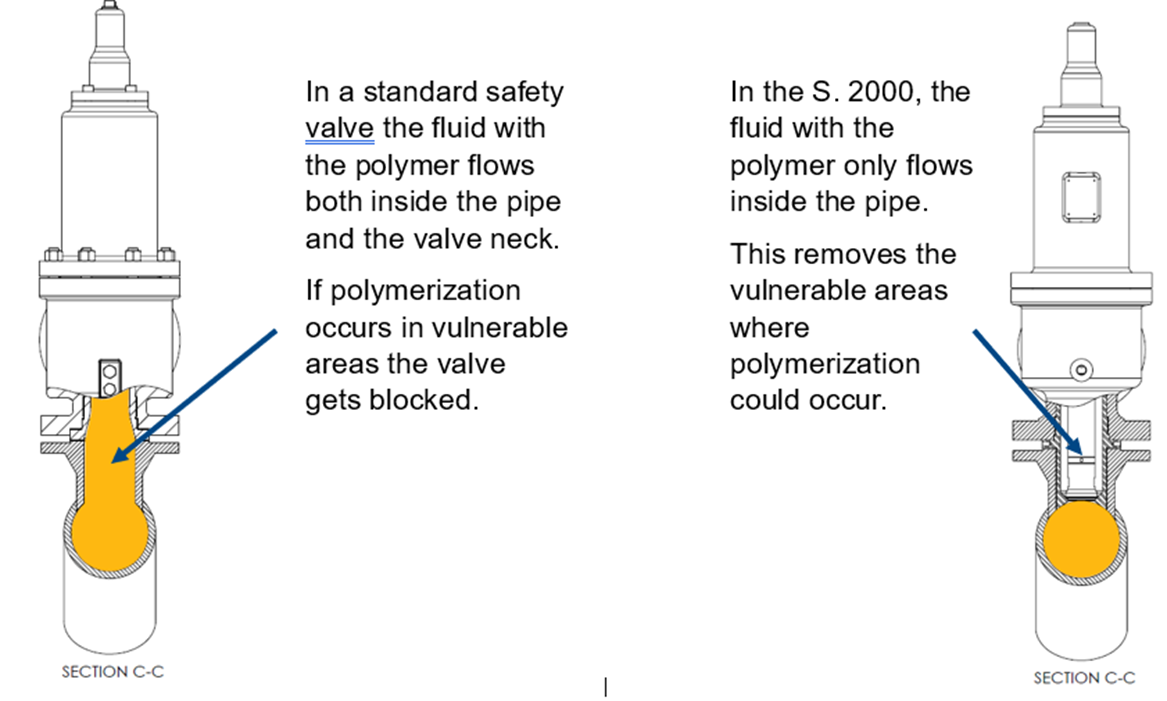

Chart's FEMA brand is synonymous around the globe for the design and manufacture of safety valves and accessories in multiple sectors, including oil and gas, cryogenics, chemicals and petrochemicals, aerospace, shipbuilding, medical and food.

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team