MicroBulk Storage Systems

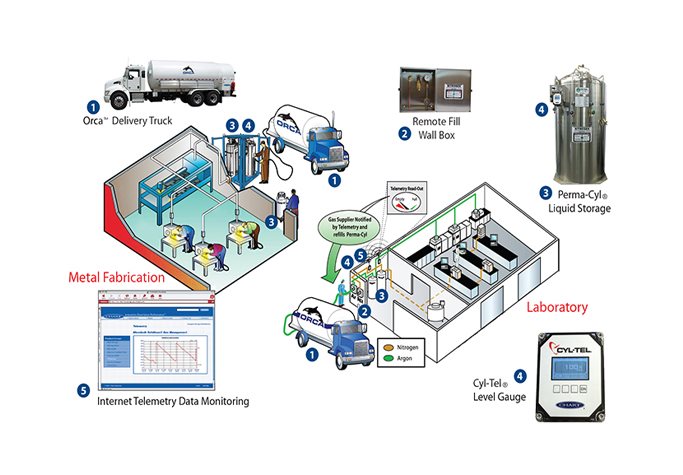

Complete gas supply and management solution that enables users of all sizes to enjoy the cost and efficiency benefits of switching to Perma-Cyl® liquid gas storage from high pressure gas cylinders.

MicroBulk systems are available for oxygen, nitrogen, argon, carbon dioxide, nitrous oxide (N2O), LNG & in high pressure, high flow applications including laser cutting, metal processing & fabrication, precision welding, laboratory & research, medical oxygen, food & beverage packaging/preservation, electronics manufacture & testing, & inert purging & blanketing.

Allowing small and medium volume users to enjoy the benefits of onsite gas delivery, Perma-Cyl MicroBulk Storage Systems provide reliable, efficient and economical solutions for liquid nitrogen, oxygen, argon, CO2, N2O and LNG.

Designed to replace high pressure gas cylinders, Perma-Cyl tanks eliminate:

Perma-Cyl tanks are designed to a higher level of thermal efficiency than competitor products, which means it holds its gas contents longer with lower pressure rise. In fact the extraordinary thermal quality of Perma-Cyl tanks limits product losses during extended periods of little, or even no, gas use.

The largest Perma-Cyl 7000 liter MicroBulk Storage System was uniquely designed to aid in a faster, higher quality laser-cut edge. It is now available to provide optimal pressures and flow rates to meet the demands of modern laser cutting operations.

Specially engineered Perma-Cyl solution for oxygen and nitrogen to serve critical medical facilities such as surgery centers, nursing homes, small hospitals, clinics, long-term care facilities, veterinary facilities, hyperbaric chambers and dental surgeries.

Digital electronic liquid level gauge designed specifically for the Perma-Cyl® MicroBulk Storage Systems. Telemetry-ready with built-in outputs that eliminate the need for additional boards and is completely compatible to most current telemetry system requirements.

Fast fill MicroBulk storage system designed specifically for CO2 applications. Incorporates many standard features from the Perma-Cyl range for easy installation, fast start-up and extended hold times, even during periods of low volume or no gas use. In addition a fast fill feature increases the fill rate from a standard beverage truck by more than 3x versus our standard Perma-Cyl series.

The Kathairos™ Solution uses liquid nitrogen to operate pneumatic devices at off-grid oil and gas facilities thereby eliminating methane emissions during routine site venting. Chart's MicroBulk system provides a continuous unattended nitrogen supply. Available for purchse or rental.

Click the live tracker and see the emissions savings to date.

Learn from the experts. Chart provides a range of training programs promoting the safe and efficient use, application and installation of our products. Learning incorporates practical and classroom sessions together with factory and site visits with all material presented and demonstrated by Chart experts.

Order replacement parts from the original equipment manufacturer. Extensive line of options and accessories including:

Need help sizing your tank? Chart has developed a Tank Sizing App that can advance your mode-change sales process faster and more accurately. No matter the challenge, Chart will provide the tools you need to succeed. Ask your Chart sales rep or email newprague.literature@chartindustries.com to get access.

Elevate your professional capabilities in the cryogenic industry with Chart University, a series of technical training events that are designed by our experts and combine classroom, practical and site learning. The aim always is to ensure graduates leave with a better understanding of how to handle and operate cryogenic gases and equipment with maximum efficiency and safety.

Chart Parts is an e-commerce platform that provides a familiar internet shopping experience for equipment spare parts, together with operating manuals and information about servicing, training events and more.

Our loyal customers have easy access to all our marketing materials through our Distributor Marketing Services website: Click to Login

View and download sales literature, technical manuals and more.

Customer Service North America (via Ratermann) +1 800 264 7793

Customer Service Latin America +1 800 400 4683

Technical Service Americas +1 800 253 1769

Customer Service Europe +420 412 507 234

Customer Service China +86 519 8596 6000

Cusomer Service India (Chart VRV) +91 8623 304 700