Axial Fans - Tuf-Lite

Tuf-Lite fans provide the highest levels of performance and efficiency in air-cooled heat exchangers, cooling towers, and air-cooled steam condensers.

Each Tuf-Lite fan incorporates proprietary advanced composite technologies and over six decades of know-how in its design. With more than 300,000 in use worldwide, Tuf-Lite is the brand chosen by the most demanding plant operators and comes with a 36 month warranty. Tuf-Lite is also the industry benchmark for low noise solutions.

Tuf-Lite® can be used as an OEM product or as a performance upgrade to improve plant reliability, air-flow, cooling performance, and energy efficiency.

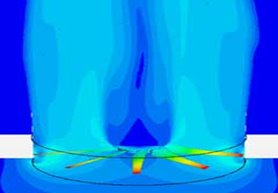

Not only do we use the latest engineering technologies, such as computational fluid dynamics and finite element analysis, we perform extensive testing and have a continuous research and development program to ensure our fans perform reliably in all environments, all of the time.

Tuf-Lite® are hand-laid-up molded fan blades with either epoxy resin or a specially formulated proprietary vinyl ester resin. Each blade has a different fiberglass configuration that is as a result of 60+ years of know-how and continuous improvement and innovation.

Tuf-Edge® is a specially designed proprietary vinyl ester resin that protects the fan blades and provides a UV resistant coating.

Home to Hudson air cooled heat exchangers and Tuf-Lite axial flow fans. Hudson pioneered the technology to solve urgent production problems in the field and today is especially synonymous with reducing costs for LNG and other mega energy projects. Tuf-Lite fans provide the highest levels of performance and efficiency in air-cooled heat exchangers, cooling towers, and air-cooled steam condensers.

Now only available in limited diameters. Contact Hudson for details.

Only available in 34', 36' and 40' fan diameters.

Can be seamlessly upgraded with Tuf-Lite III for replacement projects.

Tuf-Lite III KW is in a class of its own. The KW is the most versatile and highest performing fan in its class. The KW is a wide chord fan available from 11’-20’ in diameter. Due to its innovative design, it can be used to provide more air flow that is unmatched by any other fan, can be used for lower noise applications, is energy efficient, and is as reliable as all Hudson fans. The KW can be used in any 11’-20’ application and is most commonly used for air-cooled heat exchangers, field erected cooling towers, and package cooling towers.

Reliability

Aerodynamic Performance

Noise and Vibration

Fitting/retro-fitting Tuf-Lite axial flow fans at LNG liquefaction plants can be used to reduce the size of the overall plot with fewer air coolers required and/or increase throughput, performance and reliability of existing air coolers.

Visit our technical library to view and download supporting documentation including brochures, installation instructions, head to head performance comparisons and more.

Inquiries +1 918 619 8000

.jpg?ext=.jpg)