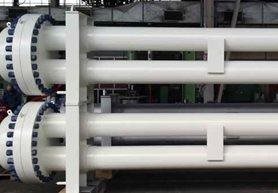

Hairpin Heat Exchangers

Hairpin heat exchangers use true counter-current flow. Unlike multi-pass shell and tube designs where correction factors are used to account for inefficiencies resulting from co-current passes, this process maximizes temperature differences between shell- and tube-side fluids.

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team