Cooling Fans

Howden’s range of industrial cooling fans are used as part of wet, dry and hybrid cooling systems. Our fans lead the way in high efficiency and low noise operation.

Howden has been at the forefront of cooling fan technology for over 60 years and continues to innovate. Our range of cooling fans consists of the D, E, SX and FPX series are proven across a diverse set of industries from oil & gas and power plants through to light industrial manufacturing plants, data centers, commercial buildings and industrial machinery engines.

A complete unit giving low-noise, high-efficiency powered by a permanent magnet motor. Whether developing cooling fan solutions for cooling towers, dry coolers, radiators, or condensers, the demand and legal requirements for energy efficiency are ever increasing. The FPX Cooling Fan Unit pairs sophisticated system technology with economic efficiency.

| CE conformity declaration - accordance with IEC/TS 60034-30-2 for efficiency class IE5 | |

| Performance - optimized airflow through the inlet bell, reducing turbulence and improving overall efficiency and lowering noise | |

| Cost effective - maintenance-free ball bearings with long-term service life of at least 40,000 hours of operation | |

| Low noise - reduces noise up to 14 dB(A) compared with standard cooling fans | |

| Complete turnkey solution - ready to install with integrated control electronics for unparalleled compactness |

The processing and refining of fossil fuels uses a range of high temperature processes from gas cracking and oil distillation to additional thermal methods to obtain final products. In many cases, equipment used within the value chain also generate high levels of heat such as compression within liquefaction or boosting for transportation. All such activities necessitate cooling systems as a result.

Downstream processingGas plants, refineries and petrochemical complexes all have cooling requirements linked to heat rejection processes as well as utility cooling. Process cooling systems can vary with the use of ACHE, CT or even Air Cooled Condensers (ACC). We supply numerous fans to customers for such plants as well as perform enhancements for operators within existing plants.

Gas compression stationsCompression and boosting the pressure of gas for pipeline transmission requires cooling for continued safe operation. Our fans are integrated into ACHEs supporting this application.

LNG productionThere is a high cooling capacity requirement for the liquefaction process. This is typically addressed with Air Cooled Heat Exchangers (ACHE) or potentially a Cooling Tower (CT). Additional cooling is needed on site for utilities such as power. Howden has experience of supplying fans of a varying sizes and configurations to the meet the demands of these applications.

The thermal combustion process used to generate electrical power inevitably results in the production of high amounts of waste heat. Where this cannot be utilised for further energy recovery, it must be rejected responsibly to atmosphere using a cooling system. These cooling systems typically circulate liquids in order to transfer heat away from the process and incorporate cooling towers, air cooled condensers (ACC) acting as condensers.

Applicable Products

Across industries, there is a common need to satisfy cooling demands caused by production processes as well as HVAC-R applications. In many cases small standardised package Cooling Towers, Air Cooled Heat Exchangers and Hybrid Coolers are used.

Data CentersComputing power requires substantial cooling capacity to dissipate heat generated. Energy efficiency is key and designs often incorporate free cooling alongside coolers. Our fans offer a flexible solution to cooling system providers aligned to this growing segment.

Applicable Products

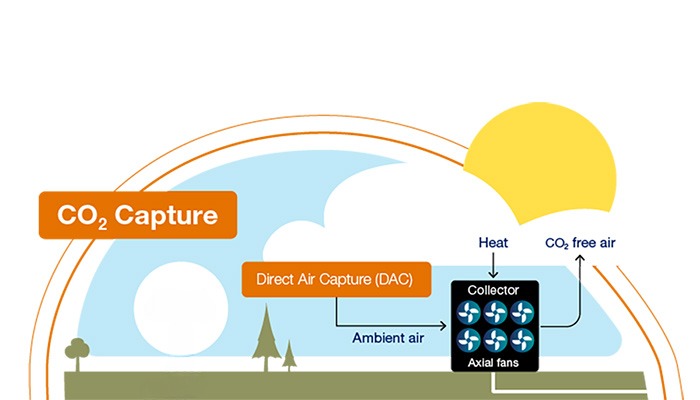

Direct Air Capture is the process of capturing CO2 directly from the ambient air either through a recirculating fluid or through a solid sorbent. This process generates a concentrated stream of CO2 for sequestration, utilisation or production of carbon-neutral fuel.

What is Howden’s role in Direct Air Capture?Howden provides the low pressure axial fans that would be mounted on top of a DAC tower to draw ambient air through a recirculating fluid or through a solid sorbent which traps the CO2 from the ambient air. From there the CO2 can be used or sequestered.

De-centralized power plants play an important role in the world of power generation as changing energy demands and flexibility increase their use. Gas fired reciprocating engine technology requires fans for radiator cooling. Alongside cooling efficiency, noise regulations are key to maintain safe operation for workers and minimize impact on local communities.

Industrial MachineryMachinery powered by internal combustion engines require fans to provide essential cooling of the radiator. This is critical for operational performance and economy. Our fans meet all the key criteria combining the necessary flow, robust construction and ultra-low noise performance.

The processing and refining of fossil fuels uses a range of high temperature processes from gas cracking and oil distillation to additional thermal methods to obtain final products. In many cases, equipment used within the value chain also generate high levels of heat such as compression within liquefaction or boosting for transportation. All such activities necessitate cooling systems as a result.

Downstream processingGas plants, refineries and petrochemical complexes all have cooling requirements linked to heat rejection processes as well as utility cooling. Process cooling systems can vary with the use of ACHE, CT or even Air Cooled Condensers (ACC). We supply numerous fans to customers for such plants as well as perform enhancements for operators within existing plants.

Gas compression stationsCompression and boosting the pressure of gas for pipeline transmission requires cooling for continued safe operation. Our fans are integrated into ACHEs supporting this application.

LNG productionThere is a high cooling capacity requirement for the liquefaction process. This is typically addressed with Air Cooled Heat Exchangers (ACHE) or potentially a Cooling Tower (CT). Additional cooling is needed on site for utilities such as power. Howden has experience of supplying fans of a varying sizes and configurations to the meet the demands of these applications.

The thermal combustion process used to generate electrical power inevitably results in the production of high amounts of waste heat. Where this cannot be utilised for further energy recovery, it must be rejected responsibly to atmosphere using a cooling system. These cooling systems typically circulate liquids in order to transfer heat away from the process and incorporate cooling towers, air cooled condensers (ACC) acting as condensers.

Applicable Products

Across industries, there is a common need to satisfy cooling demands caused by production processes as well as HVAC-R applications. In many cases small standardised package Cooling Towers, Air Cooled Heat Exchangers and Hybrid Coolers are used.

Data CentersComputing power requires substantial cooling capacity to dissipate heat generated. Energy efficiency is key and designs often incorporate free cooling alongside coolers. Our fans offer a flexible solution to cooling system providers aligned to this growing segment.

Applicable Products

Direct Air Capture is the process of capturing CO2 directly from the ambient air either through a recirculating fluid or through a solid sorbent. This process generates a concentrated stream of CO2 for sequestration, utilisation or production of carbon-neutral fuel.

What is Howden’s role in Direct Air Capture?Howden provides the low pressure axial fans that would be mounted on top of a DAC tower to draw ambient air through a recirculating fluid or through a solid sorbent which traps the CO2 from the ambient air. From there the CO2 can be used or sequestered.

De-centralized power plants play an important role in the world of power generation as changing energy demands and flexibility increase their use. Gas fired reciprocating engine technology requires fans for radiator cooling. Alongside cooling efficiency, noise regulations are key to maintain safe operation for workers and minimize impact on local communities.

Industrial MachineryMachinery powered by internal combustion engines require fans to provide essential cooling of the radiator. This is critical for operational performance and economy. Our fans meet all the key criteria combining the necessary flow, robust construction and ultra-low noise performance.

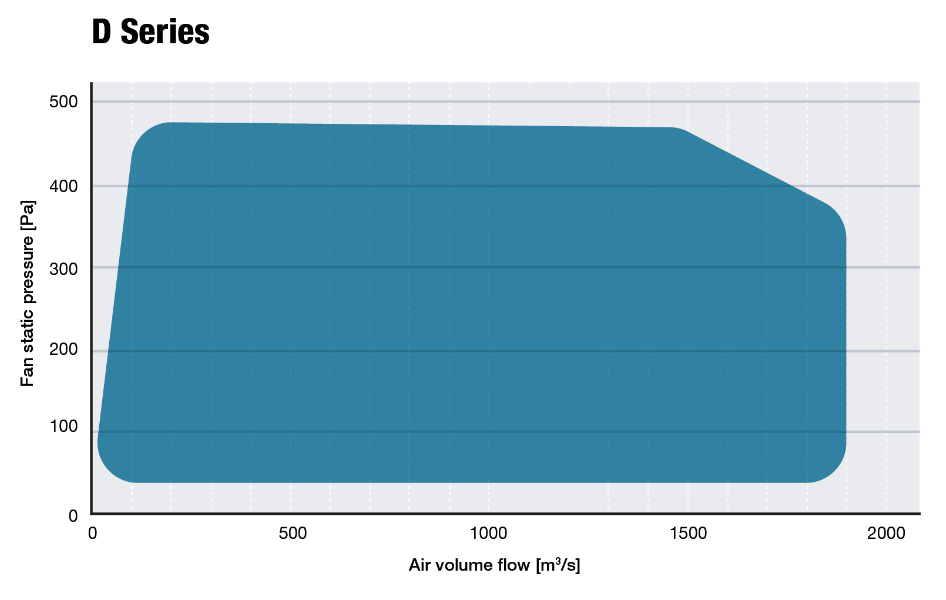

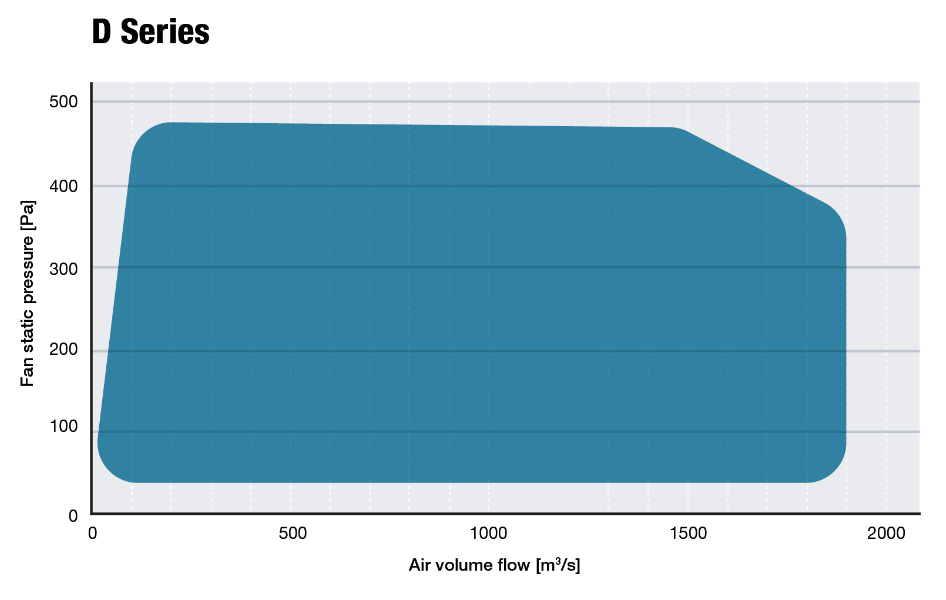

The D-Series is mainly used within Air Cooled Condensers, but can also be deployed within field-erected Cooling Towers. With its larger diameters, it is typically used within industries with significant cooling requirements such as power and large-scale energy facilities. Due to its diameter range it is not typically used within Air Cooled Heat Exchangers.

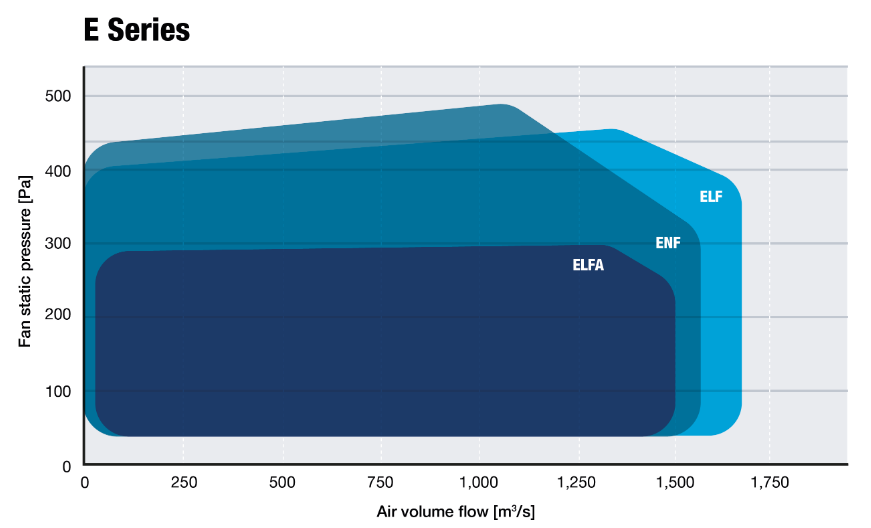

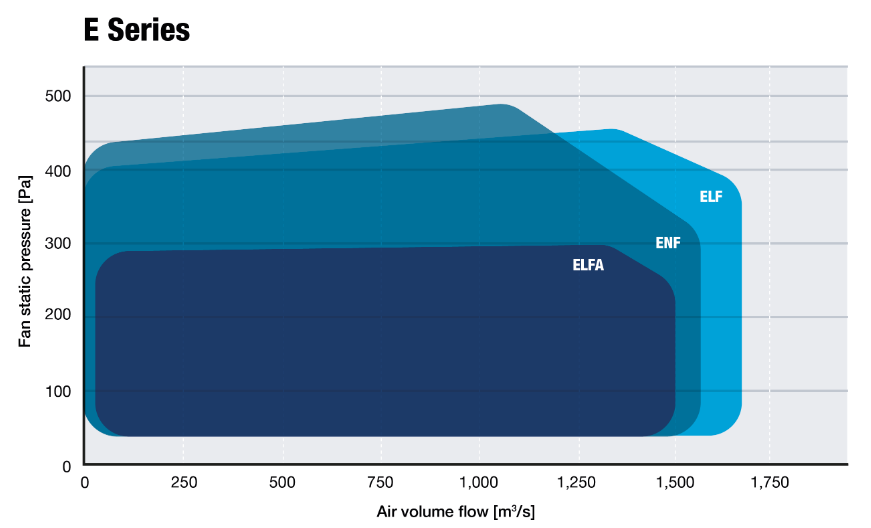

The E-series is the choice for heavy-duty situations in vertical or horizontal mounting configurations for a wide range of applications. As the E-Series has a wide diameter range and can withstand high pressures, it can be used across Cooling Towers (field erected and packaged), Air Cooled Heat Exchangers and Air Cooled Condensers.

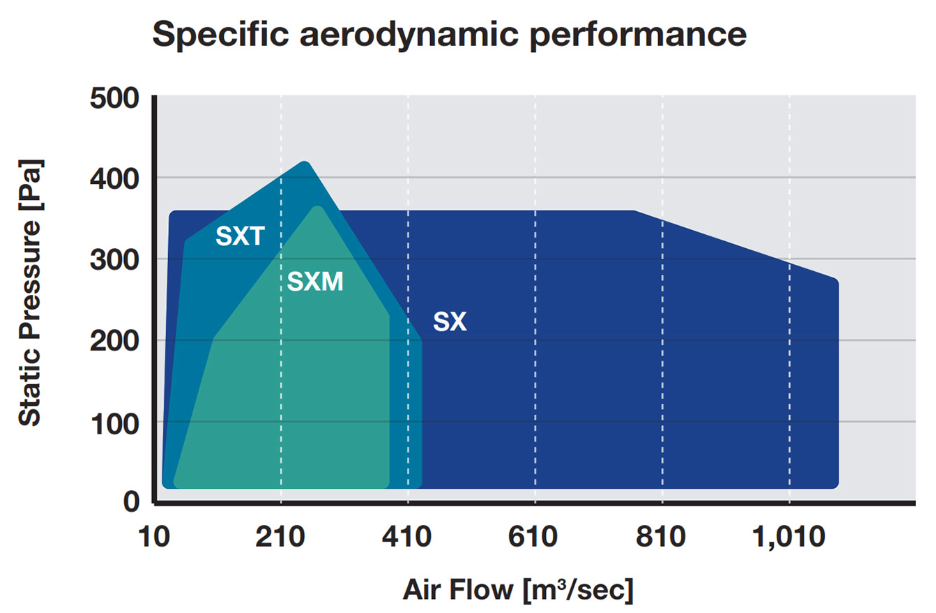

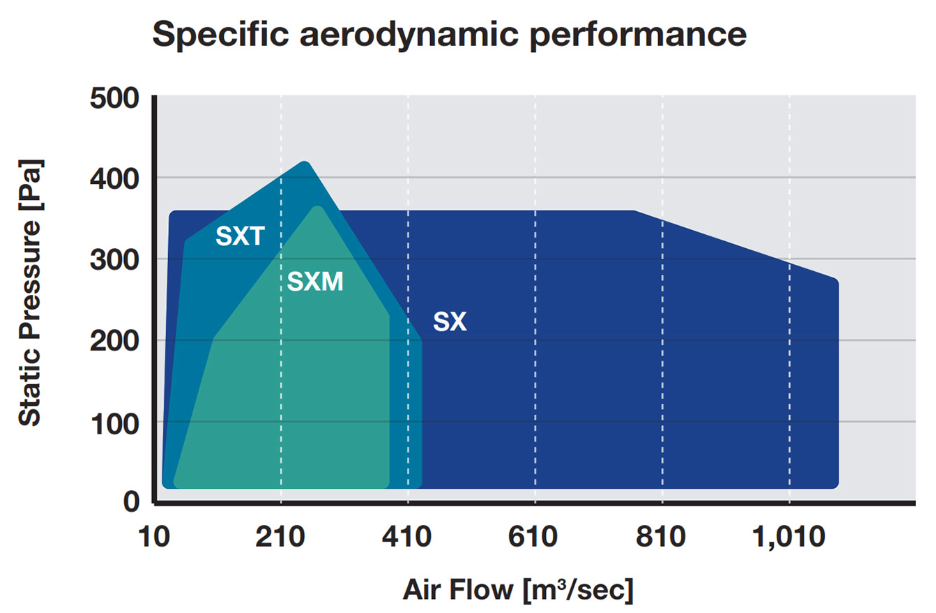

The SX-series is the preferred solution for applications with stringent noise requirements and capable of reducing noise by up to 20 dB(A) compared with standard cooling fans.

The SX-series is the ideal solution combining low noise emisions with optimal performance and can be applied in a wide range of applications. For example, Air Cooled Heat Exchangers, Cooling Towers and Air Cooled Condensers. The SXT and SXM are derived from the SX with a smaller diameter range and therefore is primarily intended for smaller Cooling Towers and Air Cooled Heat Exchangers.

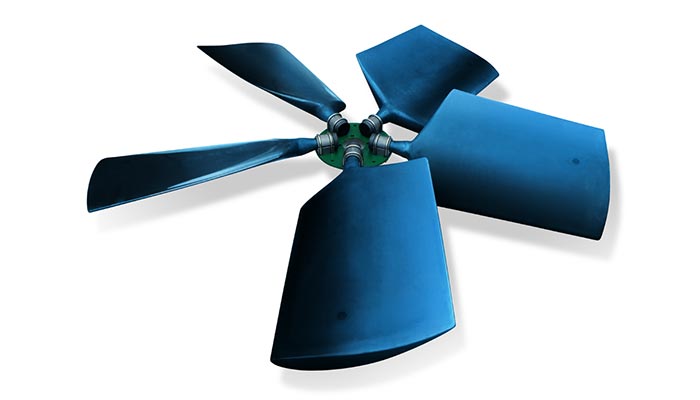

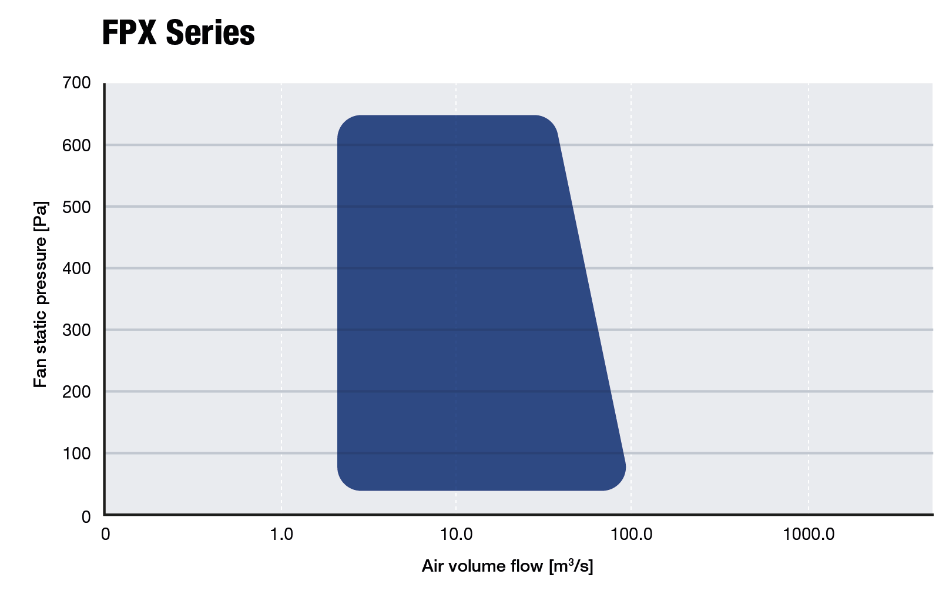

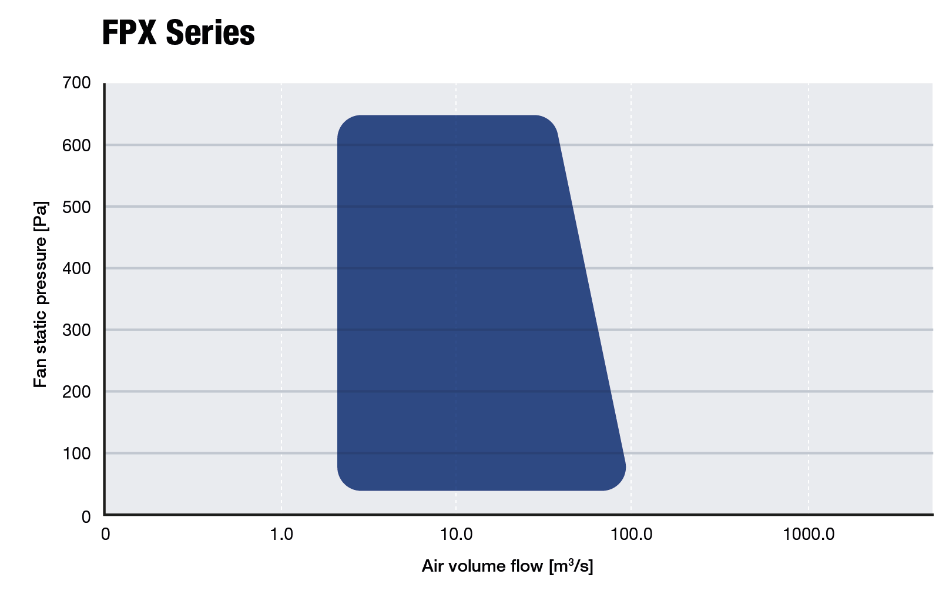

The FPX Series uses fixed-pitch ultra-low noise blades. Manufactured as a single piece impeller unit, offering very easy assembly and minimal maintenance, combined with ultra-low noise design. It is available in a wide range of diameters with different blade profiles and blade arrangements, to meet the specification of each low noise project.

Low noise fans offer the possibility to achieve optimal performance with respect to low noise, smaller footprint, increased efficiency and low Capex.

The FPXM combines a medium sized chord, full aerofoil blade profile with low noise emission and high efficiency.

The FPXM fan range reduces noise up to 14 dB(A) compared with standard cooling fans and minimizes the size of fan casings and transport cost due to the reduced chord and low weight.

The FPX series is mainly used in small standardized Cooling Towers, Air Cooled Heat Exchangers and Radiators. The FPX is also able to be deployed in Hybrid Coolers, meaning that the FPX fan can satisfy cooling demands within heavy process industries and well as HVAC-R applications.

FPX Complete UnitA complete unit giving low-noise, high-efficiency powered by a permanent magnet motor. Whether developing cooling fan solutions for cooling towers, dry coolers, radiators, or condensers, the demand and legal requirements for energy efficiency are ever increasing. The FPX Cooling Fan Unit pairs sophisticated system technology with economic efficiency.

Our Howden engineers are the finest in the world at selecting the right solution for our customers. We know that customers want to do their own selections as well though. Therefore we have concentrated our 160 years of engineering expertize into a software tool that enables you to easily create your own selections.

.jpg)

Howden’s aftermarket capabilities range from servicing and parts supply to performance upgrades and retrofits. The more advanced services can maximize the life of the fans in each system as well as keep their operation aligned to the latest technical parameters. This includes fan scans to provide insight into future repair needs, blade refurbishment to extend service life and retrofits to increase cooling capacity or reduce noise.

Howden offers a free consultation to assess the potential for enhanced performance and noise reduction and can deliver selected options on a turnkey basis.

Our expert in-house R&D department formed working partnerships with a wide range of external authorities, including universities and other institutions, to explore the optimum blade profiles, materials and mechanical configurations. We have state-of-the-art test facilities to investigate each permutation and evaluate each development.

The heart of our test facility is located in Hengelo, the Netherlands, where a full-scale test facility is located. Conveniently located at the High Tech Systems Park, the Howden Cooling Fans Competence Centre facilitates the testing and validation of all aerodynamic, mechanic, acoustic and factory repair activities. The new testing facility houses a range of assets that serve to test our latest developments in a controlled environment.

This testing facility provides a vital bridge between lab environments and real-world applications to safely test and validate our ultra-low noise axial fan technology. For example, all aerodynamic and acoustic tests are executed in a full-scale 6ft test rig, completely modelled and engineered to meet the AMCA standards. Besides this unique method, other assessments can be executed such as a full-scale mechanical and bending test. In combination with our chemical lab and our field measurements, this testing facility serves as the most valuable source for all our aerodynamic, acoustic, and reliable mechanical data, in order to provide a reliable fan solution for our customers.

The D-Series is mainly used within Air Cooled Condensers, but can also be deployed within field-erected Cooling Towers. With its larger diameters, it is typically used within industries with significant cooling requirements such as power and large-scale energy facilities. Due to its diameter range it is not typically used within Air Cooled Heat Exchangers.

The E-series is the choice for heavy-duty situations in vertical or horizontal mounting configurations for a wide range of applications. As the E-Series has a wide diameter range and can withstand high pressures, it can be used across Cooling Towers (field erected and packaged), Air Cooled Heat Exchangers and Air Cooled Condensers.

The SX-series is the preferred solution for applications with stringent noise requirements and capable of reducing noise by up to 20 dB(A) compared with standard cooling fans.

The SX-series is the ideal solution combining low noise emisions with optimal performance and can be applied in a wide range of applications. For example, Air Cooled Heat Exchangers, Cooling Towers and Air Cooled Condensers. The SXT and SXM are derived from the SX with a smaller diameter range and therefore is primarily intended for smaller Cooling Towers and Air Cooled Heat Exchangers.

The FPX Series uses fixed-pitch ultra-low noise blades. Manufactured as a single piece impeller unit, offering very easy assembly and minimal maintenance, combined with ultra-low noise design. It is available in a wide range of diameters with different blade profiles and blade arrangements, to meet the specification of each low noise project.

Low noise fans offer the possibility to achieve optimal performance with respect to low noise, smaller footprint, increased efficiency and low Capex.

The FPXM combines a medium sized chord, full aerofoil blade profile with low noise emission and high efficiency.

The FPXM fan range reduces noise up to 14 dB(A) compared with standard cooling fans and minimizes the size of fan casings and transport cost due to the reduced chord and low weight.

The FPX series is mainly used in small standardized Cooling Towers, Air Cooled Heat Exchangers and Radiators. The FPX is also able to be deployed in Hybrid Coolers, meaning that the FPX fan can satisfy cooling demands within heavy process industries and well as HVAC-R applications.

FPX Complete UnitA complete unit giving low-noise, high-efficiency powered by a permanent magnet motor. Whether developing cooling fan solutions for cooling towers, dry coolers, radiators, or condensers, the demand and legal requirements for energy efficiency are ever increasing. The FPX Cooling Fan Unit pairs sophisticated system technology with economic efficiency.

Our Howden engineers are the finest in the world at selecting the right solution for our customers. We know that customers want to do their own selections as well though. Therefore we have concentrated our 160 years of engineering expertize into a software tool that enables you to easily create your own selections.

.jpg)

Howden’s aftermarket capabilities range from servicing and parts supply to performance upgrades and retrofits. The more advanced services can maximize the life of the fans in each system as well as keep their operation aligned to the latest technical parameters. This includes fan scans to provide insight into future repair needs, blade refurbishment to extend service life and retrofits to increase cooling capacity or reduce noise.

Howden offers a free consultation to assess the potential for enhanced performance and noise reduction and can deliver selected options on a turnkey basis.

Our expert in-house R&D department formed working partnerships with a wide range of external authorities, including universities and other institutions, to explore the optimum blade profiles, materials and mechanical configurations. We have state-of-the-art test facilities to investigate each permutation and evaluate each development.

The heart of our test facility is located in Hengelo, the Netherlands, where a full-scale test facility is located. Conveniently located at the High Tech Systems Park, the Howden Cooling Fans Competence Centre facilitates the testing and validation of all aerodynamic, mechanic, acoustic and factory repair activities. The new testing facility houses a range of assets that serve to test our latest developments in a controlled environment.

This testing facility provides a vital bridge between lab environments and real-world applications to safely test and validate our ultra-low noise axial fan technology. For example, all aerodynamic and acoustic tests are executed in a full-scale 6ft test rig, completely modelled and engineered to meet the AMCA standards. Besides this unique method, other assessments can be executed such as a full-scale mechanical and bending test. In combination with our chemical lab and our field measurements, this testing facility serves as the most valuable source for all our aerodynamic, acoustic, and reliable mechanical data, in order to provide a reliable fan solution for our customers.

Head Office +31 74 255 6000