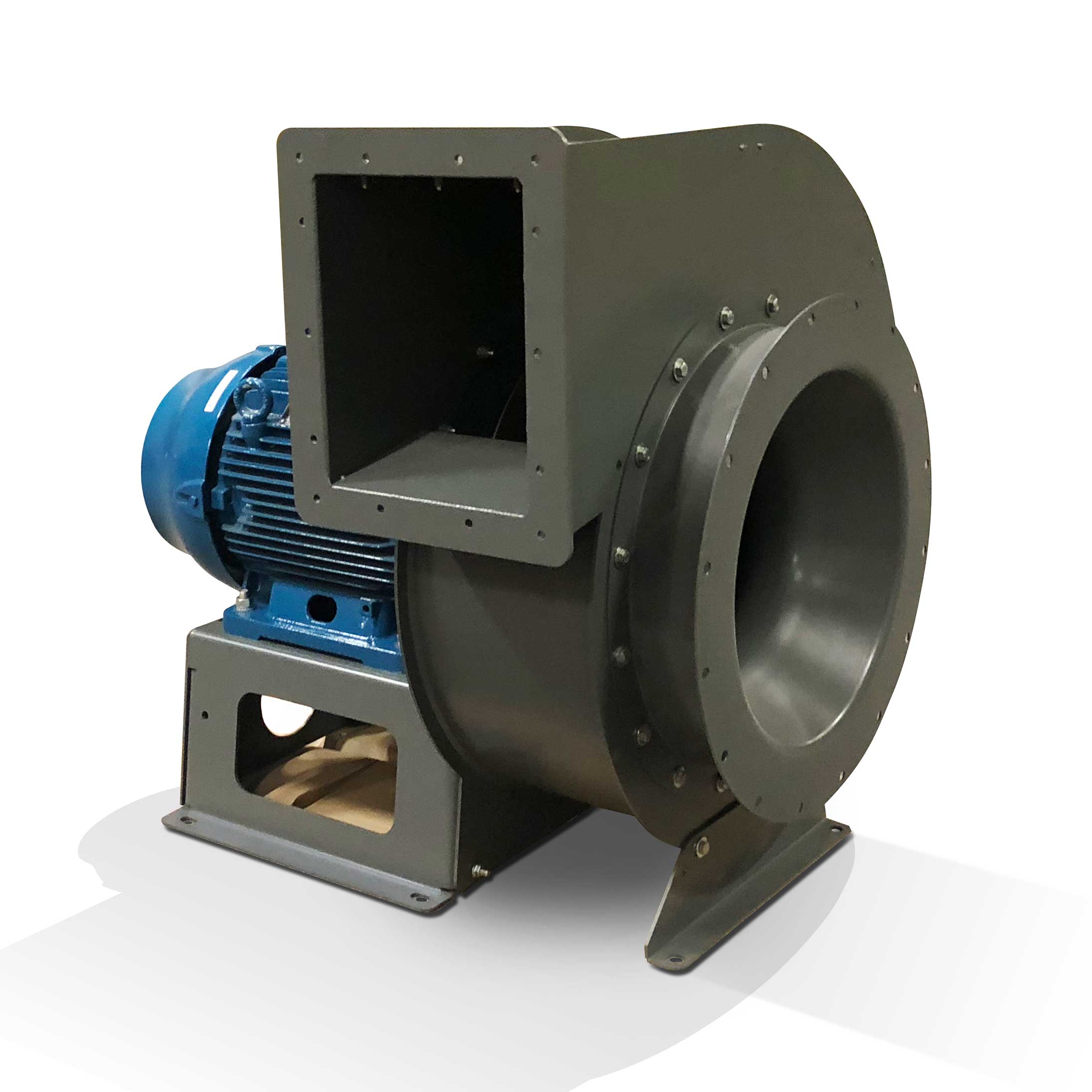

Centrifugal Fans

Howden centrifugal fans provide high efficiency air supply to critical and demanding processes. Frequently used in highly contaminated airstreams, material-handling applications, and in systems that require flow of air or gas at high temperatures.

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team