Gas Gas Heater

Supporting efficient environmental emission controls for carbon-based power plants by reducing the need for additional heating of treated gas.

Howden supplied some of the world’s first flue gas desulfurization (FGD) systems in 1934 and our gas gas heaters have become synonymous with FGD and SCR. Our equipment is ideally suited to the treatment of ‘dirty’ gases providing exceptional resistance to the cool, moist acidic conditions associated with such applications, where fouling and corrosion are a constant challenge.

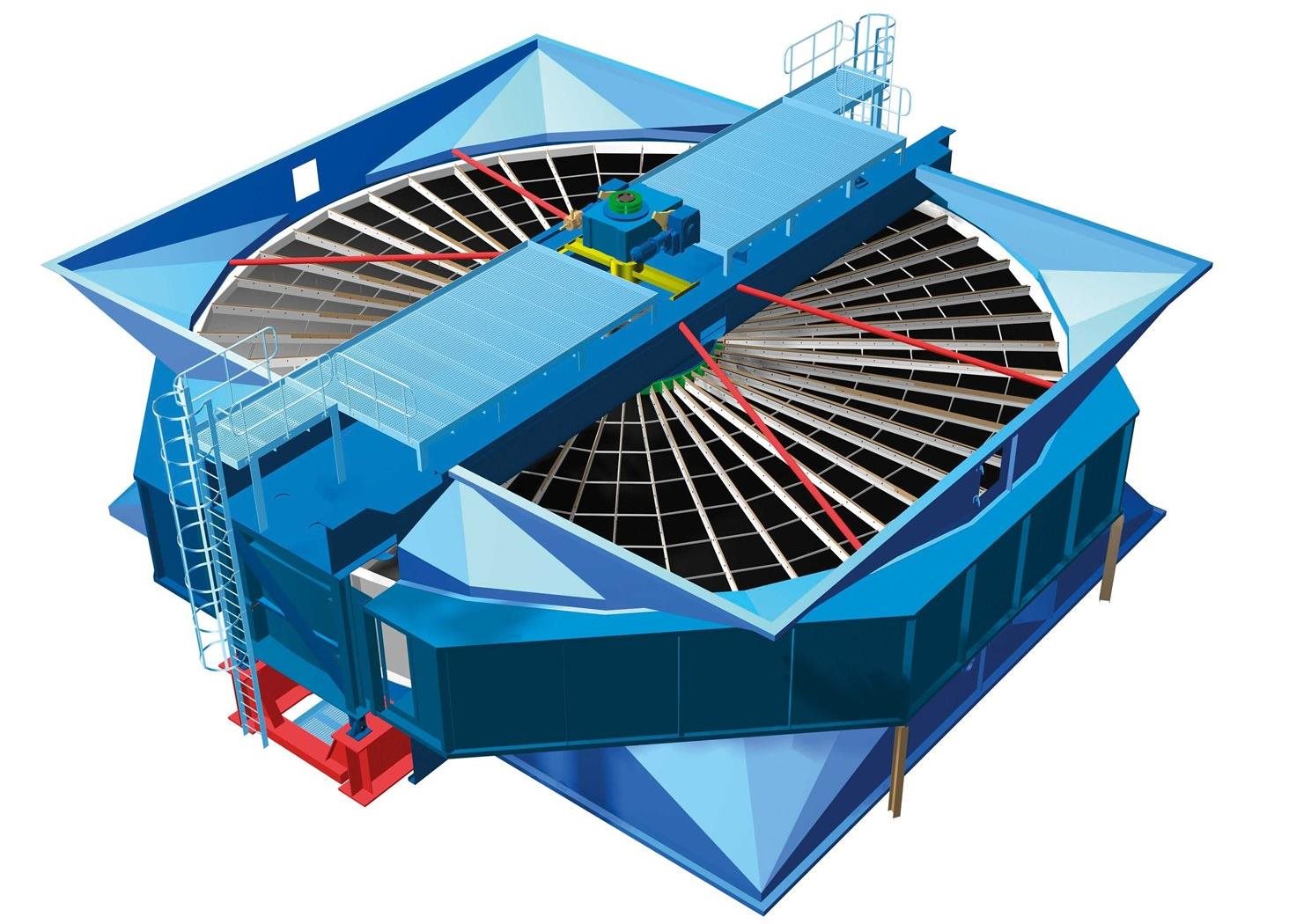

Howden’s Gas Gas Heaters are based on decades of engineering expertise and are designed as custom solutions to match the exact process duty.

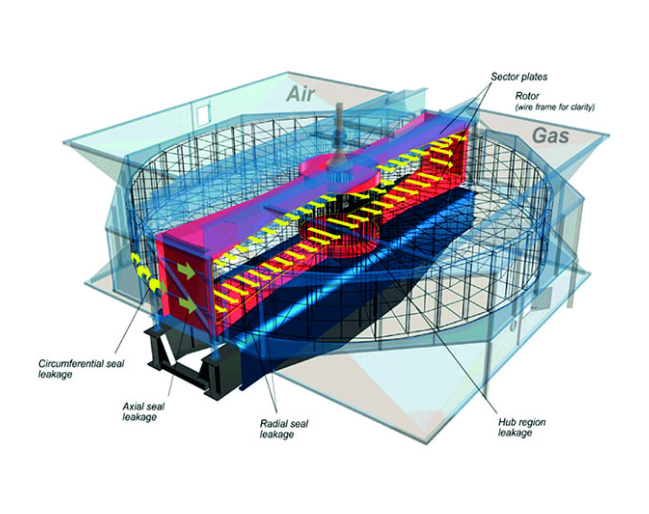

The heater is configured in a bi-sector arrangement and positioned vertically according to the process demands. Each heater is supplied with a central drive system, VN sealing system, advanced cleaning systems and element profiles selected from our wide range to maximise performance.

Leakage of untreated gas (UTG) to treated gas (TG) is addressed by VN sealing system combined with active purge and scavenge systems resulting typically in less than 0.5% of UTG flow. Booster fan position can greatly affect this too, with a B or C position booster fan resulting in leakage of 0.1%.

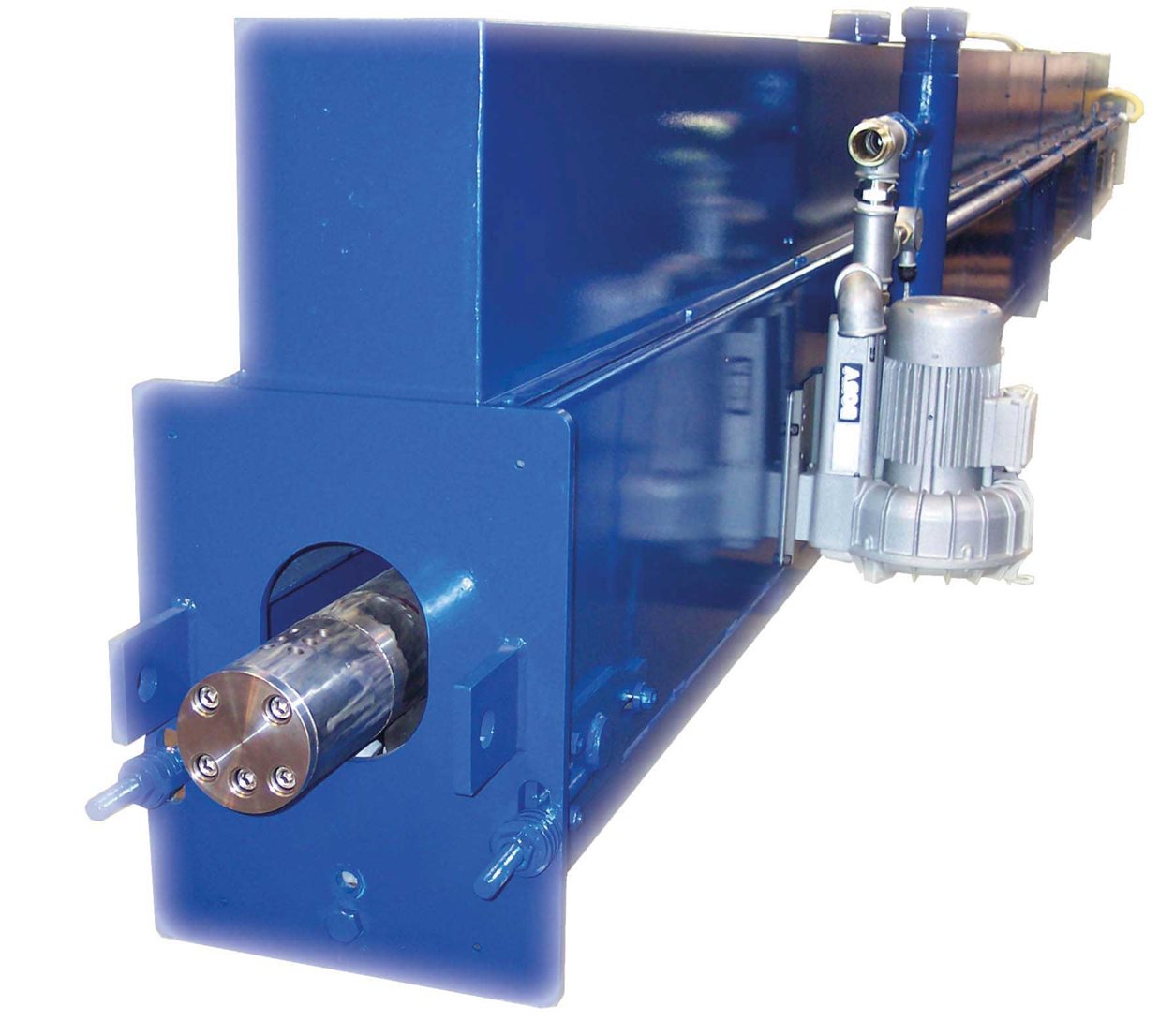

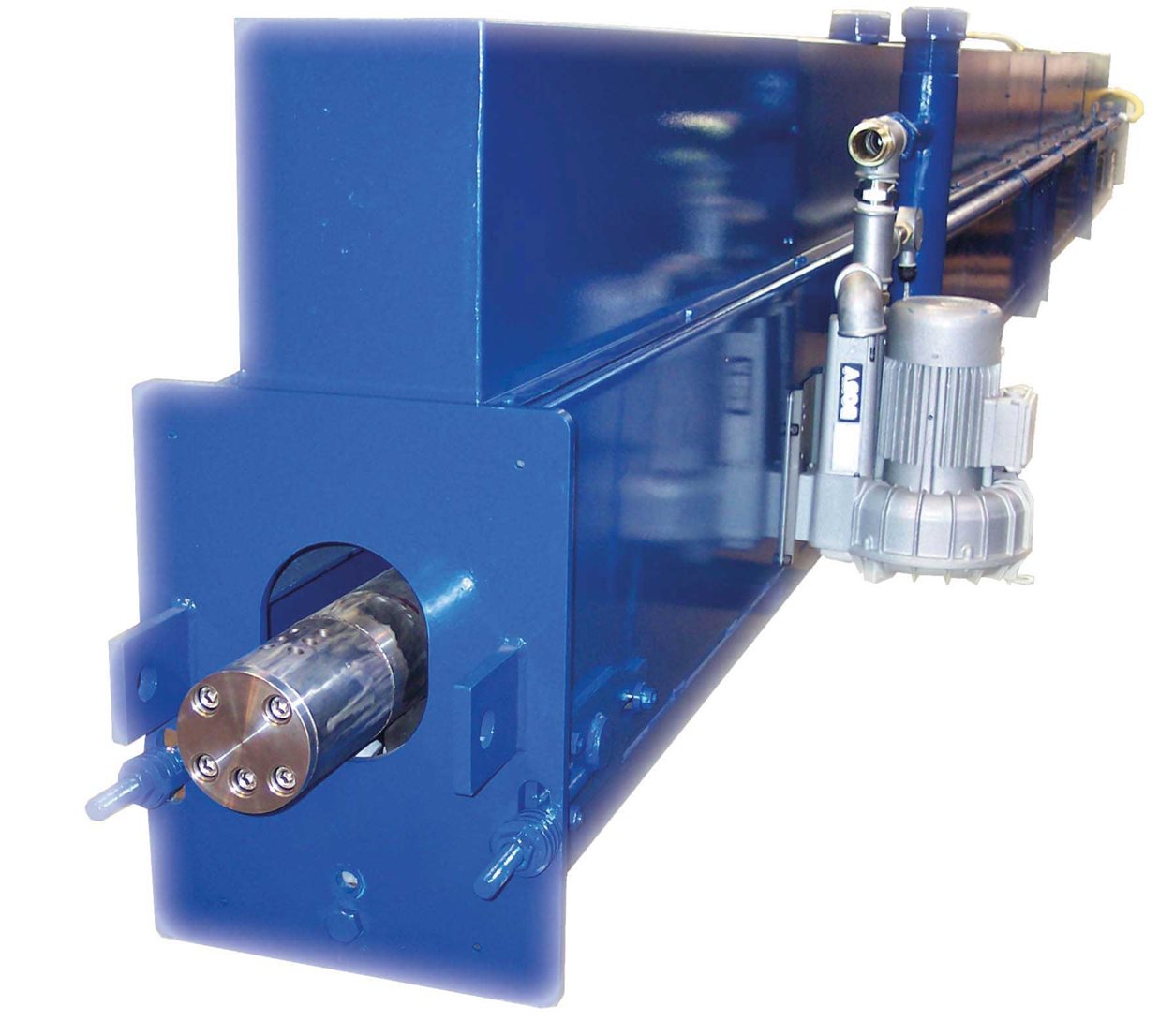

The Howden Enerjet™ cleaning system is a method of on-line high-pressure water washing of air preheaters, designed to provide effective and efficient cleaning of severely fouled heat exchanger elements while the air preheater is in normal use.

The Enerjet™ system can be used with any type of gas gas heater from any manufacturer, and works well with most kinds of element profile.

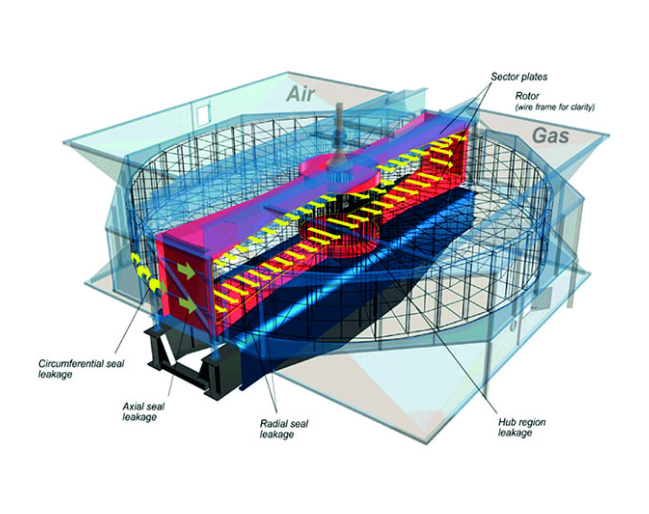

Flexible contact seals for rotary heat exchangers are a method of minimising the direct leakage gaps between the hot end of the rotor and the sectorplates, which separate the air and gas flows.

Standard seals fail due to constant flexing, therefore Howden carried out an extensive development programme to optimise contact seals for suitable applications providing major leakage reductions. As the seals work best in situations where gaps are small and even, leakage reduction can be enhanced further by combining with parabolic sectorplates.

Download our product leaflet for more information.

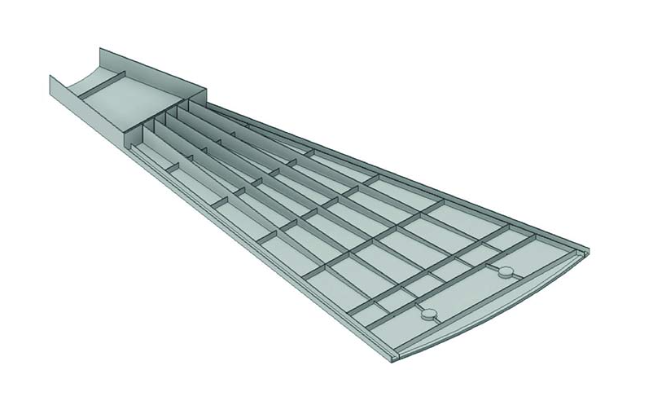

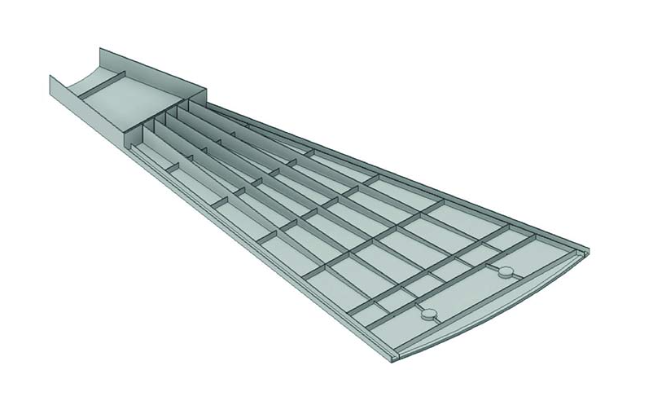

Increased environmental scrutiny and demand for the highest levels of efficiency have driven Howden to develop parabolic sectorplates (patent pending) for use with our heaters.

Hot End Sectorplates are designed with variable stiffness to deform parabolically, when actuated, to match the shape of the deformed operating rotor. This minimises the hot end leakage gap.

Howden parabolic sectorplates not only reduce draft fan power in the plant, but also reduce the gas mass flow to downstream emissions reduction equipment.

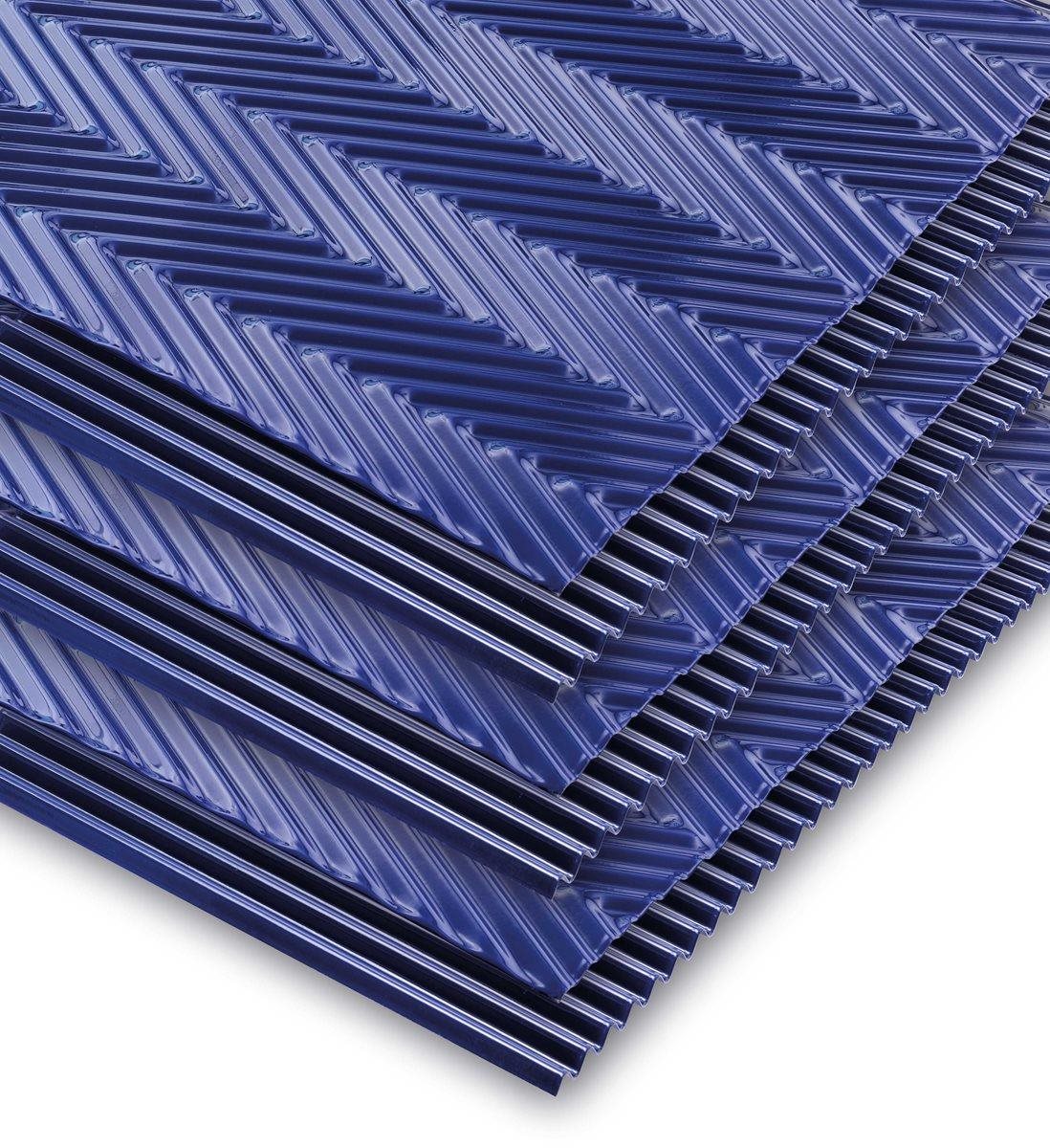

Our wide range of profiles, enables us to offer the right balance of thermodynamic performance, pressure drop and ease of cleaning for any situation. These profiles can be chosen from our range (which includes the world's first commercially available dual-profile element), or we can match existing profiles that you have already.

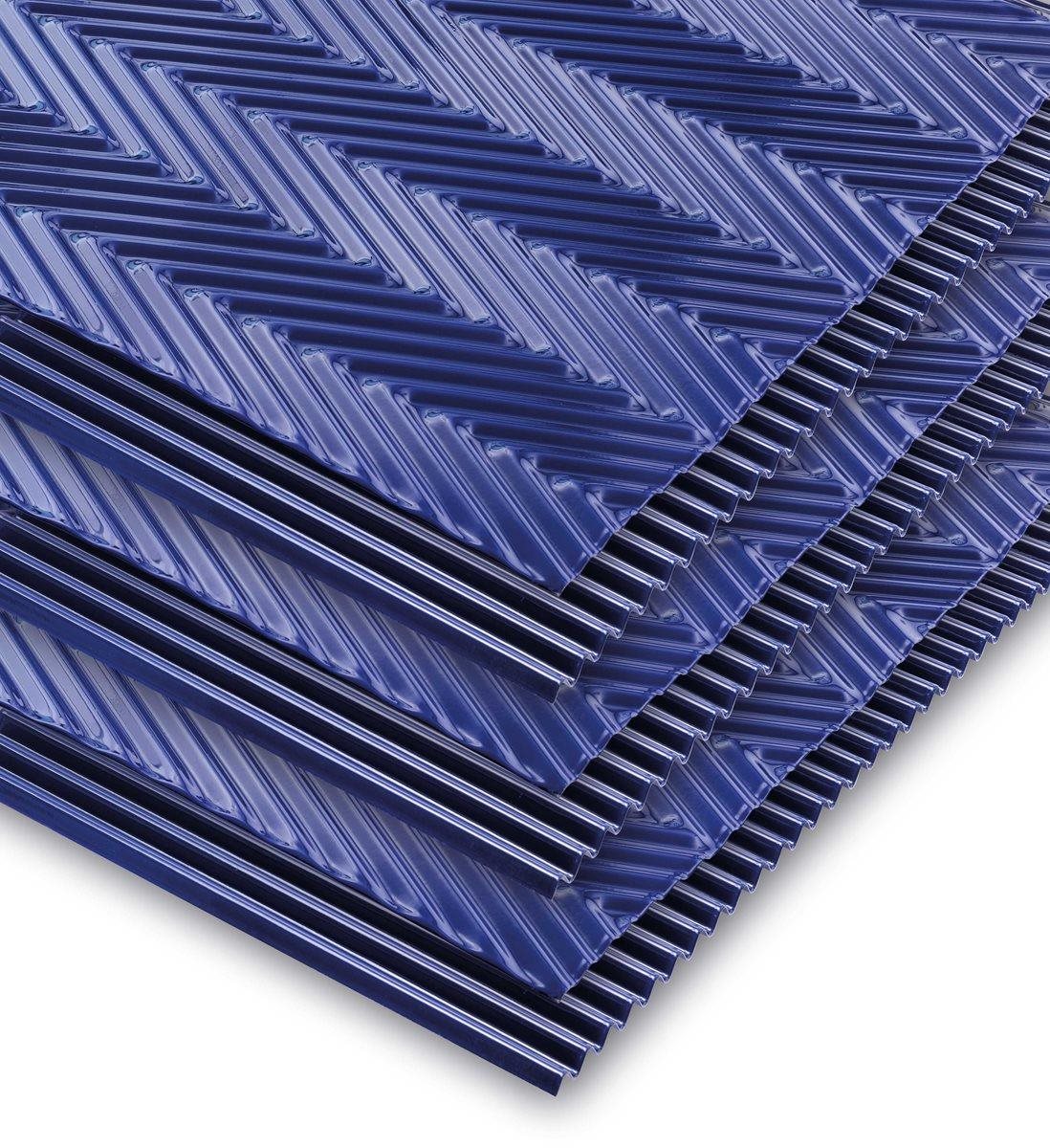

We are the world's leader when it comes to producing enamelled elements, which offer a combination of both corrosion protection and good cleanliness when used in rigorous environments.

SureCoat™ + SurePack™ + Enerjet™ - by taking a systematic view to the science of the contamination and cleaning cycle we have evolved an integrated system that delivers more than the sum of its parts.

Our service capability encompasses all rotary heat exchangers with our own brands being Howden, Sirocco, Tallares Sanchez Luengo (TSL) and Rothemühle (including LUGAT). We can offer a range of engineering services to assess and implement performance improvements and life extensions.

Howden’s Gas Gas Heaters are based on decades of engineering expertise and are designed as custom solutions to match the exact process duty.

The heater is configured in a bi-sector arrangement and positioned vertically according to the process demands. Each heater is supplied with a central drive system, VN sealing system, advanced cleaning systems and element profiles selected from our wide range to maximise performance.

Leakage of untreated gas (UTG) to treated gas (TG) is addressed by VN sealing system combined with active purge and scavenge systems resulting typically in less than 0.5% of UTG flow. Booster fan position can greatly affect this too, with a B or C position booster fan resulting in leakage of 0.1%.

The Howden Enerjet™ cleaning system is a method of on-line high-pressure water washing of air preheaters, designed to provide effective and efficient cleaning of severely fouled heat exchanger elements while the air preheater is in normal use.

The Enerjet™ system can be used with any type of gas gas heater from any manufacturer, and works well with most kinds of element profile.

Flexible contact seals for rotary heat exchangers are a method of minimising the direct leakage gaps between the hot end of the rotor and the sectorplates, which separate the air and gas flows.

Standard seals fail due to constant flexing, therefore Howden carried out an extensive development programme to optimise contact seals for suitable applications providing major leakage reductions. As the seals work best in situations where gaps are small and even, leakage reduction can be enhanced further by combining with parabolic sectorplates.

Download our product leaflet for more information.

Increased environmental scrutiny and demand for the highest levels of efficiency have driven Howden to develop parabolic sectorplates (patent pending) for use with our heaters.

Hot End Sectorplates are designed with variable stiffness to deform parabolically, when actuated, to match the shape of the deformed operating rotor. This minimises the hot end leakage gap.

Howden parabolic sectorplates not only reduce draft fan power in the plant, but also reduce the gas mass flow to downstream emissions reduction equipment.

Our wide range of profiles, enables us to offer the right balance of thermodynamic performance, pressure drop and ease of cleaning for any situation. These profiles can be chosen from our range (which includes the world's first commercially available dual-profile element), or we can match existing profiles that you have already.

We are the world's leader when it comes to producing enamelled elements, which offer a combination of both corrosion protection and good cleanliness when used in rigorous environments.

SureCoat™ + SurePack™ + Enerjet™ - by taking a systematic view to the science of the contamination and cleaning cycle we have evolved an integrated system that delivers more than the sum of its parts.

Our service capability encompasses all rotary heat exchangers with our own brands being Howden, Sirocco, Tallares Sanchez Luengo (TSL) and Rothemühle (including LUGAT). We can offer a range of engineering services to assess and implement performance improvements and life extensions.

Access and download literature, specifications, case studies and more.

Head Office +44 141 885 7500

Package Heaters +34 968 32 00 64